–CNC turning and CNC milling are the two most favored CNC machines. Equally machining procedures are important, and, it’s safe to state, they might deal with many of the perform in an average machine shop.

Phase 1: Initial, the CNC machining process starts off with a CAD model, a 3D design made on the CAD software for the specified shape and size to get created. It's possible you'll both choose to design and style the aspect you When you've got the skills, or Have got a designer build the design.

To harness a CNC turning machine complete opportunity, it’s essential to follow very best tactics in programming and operation. Below’s an extensive tutorial, which includes software options, programming strategies, and troubleshooting procedures:

The CNC machine starts functioning right after getting Recommendations from a pc-aided design and style (CAD) file. The components of the CNC lathe machine, including the rotating spindle in which the workpiece is held along with the cutting tool, do the job in unison to produce an element matching the detailed specifications outlined during the CAD file.

EDM machines use existing discharges and An electrical discipline to eliminate chips with the workpiece. Two electrodes are made use of, with electrical fields intensified by shifting the electrodes nearer to one another to be able to cut pieces. A dielectric liquid separates the two electrodes and facilitates the voltage.

The main distinction concerning horizontal and vertical CNC lathes lies of their orientation as well as programs they’re finest suited for.

Once the set up is finish, another step will be to system the CNC machine with particular instructions for your turning Procedure. This involves:

The cookie is ready through the GDPR Cookie Consent plugin and is particularly utilized to shop whether or not consumer has consented to using cookies. It doesn't retail outlet any individual details.

Delving into the workings of the CNC lathe unveils a symphony of precision engineering and computerized control. In contrast to a manual lathe, exactly where the craftsmanship lies mainly within the hands of your operator, a CNC lathe integrates computerized technology to reinforce precision and efficiency. In this article’s an in depth check out its approach:

Precision and Accuracy: CNC lathes give appreciably higher precision and consistency compared to standard lathes.

The appearance of Laptop technology was the catalyst that transformed conventional lathes into your highly complex CNC lathes we know now.

This Site takes advantage of cookies to enhance your working experience As you navigate by means of the web site. Out of those, the cookies which have been classified as important are saved on the browser as they are essential for the Functioning of standard functionalities of the website.

CNC routers are similar in form to CNC milling machines – they the two characteristic a rotating chopping head. Routers nonetheless are superior for softer materials, especially Wooden, since they are usually fewer highly effective and precise, and a far more for hobbyists and less industrial uses.

Now it’s time and energy to just take a single last end pass on this listing of CNC machines. In general, right get more info after reviewing Each and every machine and likely about each individual brochure and thoroughly assessing the technical specs of each lathe, I've come to a person conclusion:

Emilio Estevez Then & Now!

Emilio Estevez Then & Now! Amanda Bearse Then & Now!

Amanda Bearse Then & Now! Jurnee Smollett Then & Now!

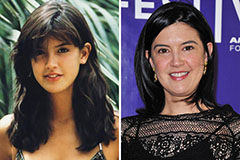

Jurnee Smollett Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Kane Then & Now!

Kane Then & Now!